How to Choose the Right Automatic Fabric Cutting Machine for Your Business

As technology continues to advance, businesses in the textile industry are constantly looking for ways to improve efficiency and productivity. One area that has seen significant advancements in fabric cutting. Gone are the days of manual cutting with scissors or rotary cutters. Automatic fabric-cutting machines have revolutionized the way fabrics are cut, making the process faster, more accurate, and less labor-intensive.

1. Cutting Method

There are different cutting methods used in automatic fabric-cutting machines. The most common methods include straight knife cutting, round knife cutting, and band knife cutting. You can also pop over here https://www.omni-cnc.com/product/digital-cutting-machine/ if you want to choose the right automatic fabric-cutting machine for your business.

2. Cutting Width and Length

The cutting width and length of the machine are important factors to consider, as they determine the maximum size of fabric that can be cut.

3. Cutting Speed

The cutting speed of the machine is another crucial factor to consider. The speed at which the machine cuts the fabric directly affects productivity and efficiency.

4. Accuracy and Precision

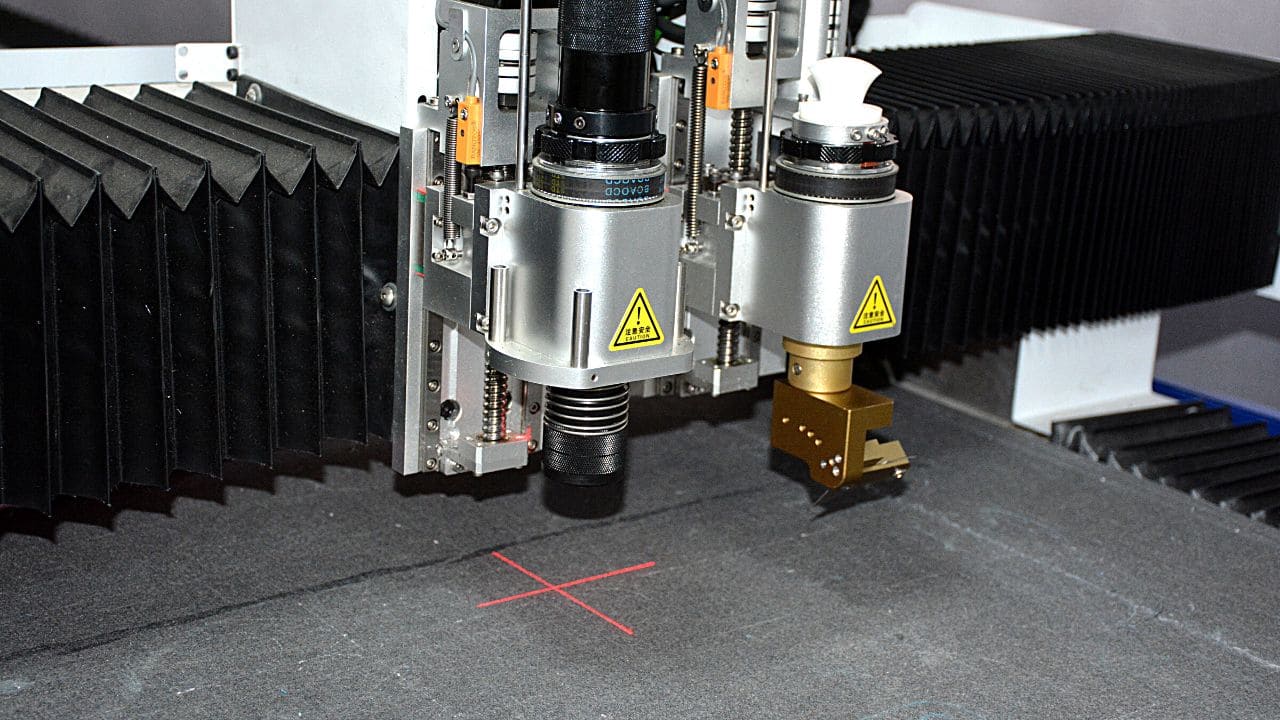

When it comes to fabric cutting, accuracy, and precision are of utmost importance. The machine should be able to consistently cut fabrics with minimal errors or variations. Look for machines that have advanced cutting technologies and features such as laser guidance systems or computerized controls.

5. Automation and Software Compatibility

Automatic fabric-cutting machines can be equipped with various automation features to further enhance productivity. Look for machines that offer features such as automatic feeding and stacking, barcode scanning, or pattern recognition.

Conclusion

Choosing the right automatic fabric-cutting machine for your business is a critical decision that can impact productivity and efficiency. By considering factors such as cutting method, cutting width and length, cutting speed, accuracy and precision, automation and software compatibility, and maintenance and support, you can make an informed decision that meets your specific requirements.